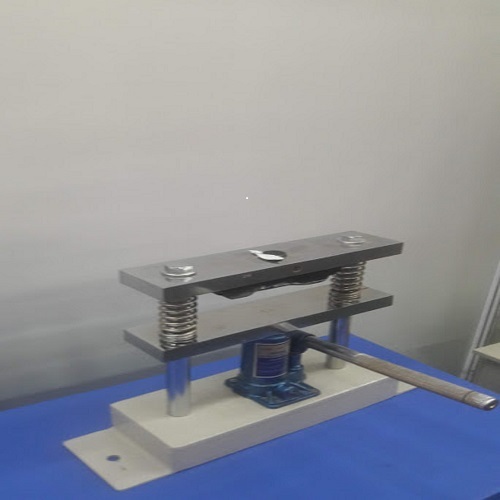

Hydraulic Press

Product Details:

- Length 950 Millimeter (mm)

- Weight 1500 Kilograms (kg)

- Width 500 Millimeter (mm)

- Height 2000 Millimeter (mm)

- Size 650x500x2000mm.

- Color Bule

- Dimension (L*W*H) 650x500x2000mm. Millimeter (mm)

- Click to View more

Hydraulic Press Price And Quantity

- 900000 INR/Unit

- 1 Number

Hydraulic Press Product Specifications

- 950 Millimeter (mm)

- 650x500x2000mm. Millimeter (mm)

- Digital hydraulic

- 650x500x2000mm.

- 1500 Kilograms (kg)

- Electrical

- Bule

- 15 Watt (w)

- 2000 Millimeter (mm)

- 500 Millimeter (mm)

- 220 Volt (v)

Hydraulic Press Trade Information

- Mumbia

- Others

- 15 Number Per Month

- 30 Days

- Australia South America Western Europe Middle East Africa Central America Asia Eastern Europe North America

- All India

- ISO,CE

Product Description

Hydraulic PressSpecification

Type: Up stroking, double acting with heated platens

Capacity: 80 tonnes (80,000 kg)

Temperature: 350 dgree C (Maximum continuous use temperature). The heating system will be designed accordingly which is controllable through PLC. Temperature accuracy plus and minus 1drgee C. The heaters will be chosen for achieving a heating rate of 1dgree C (min.) to 50C (max) per min.

Heaters and insulation: Each platen will be provided with a heating arrangement to achieve the temperature requirement described above.The platens will be adequately insulated so that heat is not passed on to the hydraulic

system.

Ram size: 205mm

Daylight Opening: 300 mm

Speed (close/press/open in mm/min): 300/10/400

Hydraulics: Double acting cylinder with dual pressure/ volume system. Integral hydraulic reservoir with a suction strainer and oil lever indicator, Integral hydraulic reservoir will be easily accessible for cleanoutoperation

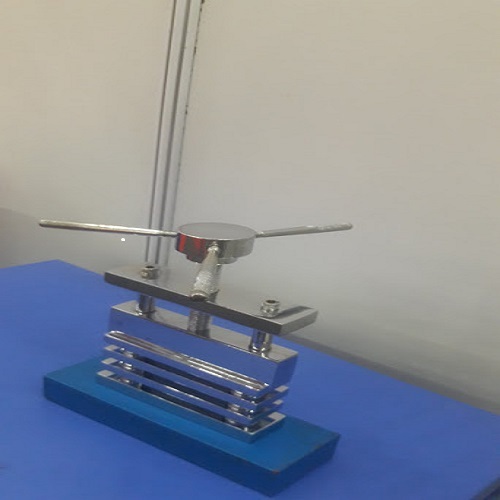

Platens: Precision-ground steel platens of size 400 mm x 400mm, electrically heated.The platens will be perfectly parallel to each other (When they are in a closed position,the light will not pass through).

Electrical: The hydraulic press and the heaters will be operated through a PLC, 3 phase (415 V) power supply. Total power consumption : 15 kw

Gauges and Valves: Suitable hydraulic pressure gauge with a pressure control valve will be provided.Range of pressure gauge: 240barLest count: 1 bar

Control Console: PLC based Control Console will be provided with the system. This control console will be suitable for carrying out the following operations:

i) Will control the hydraulics for the upstroke and down stroke.

ii) Will control the closing/pressing/opening speed as perthe specification

iii) Heating of each platen will be controlled independently through PLC to achieve the accuracy of plus an minus1dgree C between the set temperature and temperature achieved.

iv) Overheating protection will be provided through PLC for each platen.

v) Emergency/Stop knob will be provided in the Control Panel.

vi) Indicator light for heaters will be provided in the control panel. Emergency indicator lamp and alarm will be

provided, which are to be mounted on the top of hydraulic press.

Press Construction: The construction of the machine will be four pillar type, which is most suitable for maintaining the parallelism of the platens and can be adjustable to any future development to press. It is better than welded structure of press which cannot be modified. The construction will be such there will beno deflection of the frame while applying load. Internal rods with bronze bushes will be provided for guiding the platens.

Dimension and weight: 1500kg.

Dimension of load frame: LxWxH: 650x500x2000mm.

Optional:

i) Digital hydraulic pressure gauge

ii) Programmable Segment Control systems for upper and lower platens separately for programming heating rate, soaking time, cooling rate.

iii) HMI7Make: Siemens

iv) Heaters (Tubular)Make: Jai Shree

v) Hydraulic oil Make: Servo system 68

vi) Electronics: Siemens

vii)Hydraulics: Yuken Polyhydron

viii) Control System: Siemens

ix) Hydraulic Cylinder: INNOTECH Make

Other Products in 'Hydraulic Press Machine ' category

|

INNOTECH ENGINEERING DEVICES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese