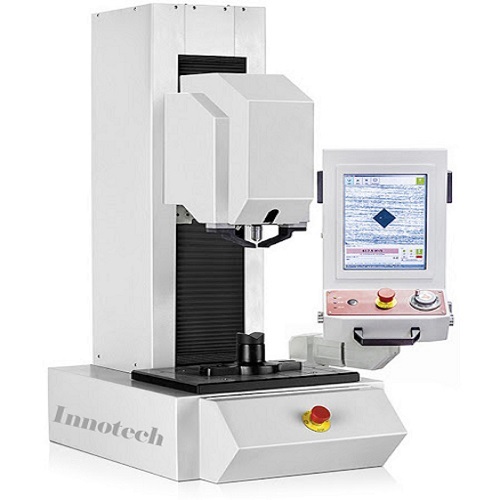

Automatic Rockwell Hardness Tester

Product Details:

- Dimension (L*W*H) 700*300*900 Millimeter (mm)

- Number of Specimens 3

- Temperature 5 to 50 degree C Celsius (oC)

- Humidity 85

- Application Hardness testing

- Power Supply AC220V/50Hz

- Test Range 20-100

- Click to View more

Automatic Rockwell Hardness Tester Price And Quantity

- 1 Number

- 1200000 INR/Unit

- 1000000.00 - 1200000.00 INR/Unit

Automatic Rockwell Hardness Tester Product Specifications

- 700*300*900 Millimeter (mm)

- 125 Kilograms (kg)

- 200m Millimeter (mm)

- 3

- 5 to 50 degree C Celsius (oC)

- Automatic

- 85

- AC220V/50Hz

- 20-100

- Hardness testing

- 150

- 125 Kilograms (kg)

- Industrial

- Industrial

- White

Automatic Rockwell Hardness Tester Trade Information

- Mumbai

- Others

- 30 Number Per Month

- 30 Days

- Australia North America South America Eastern Europe Western Europe Middle East Africa Central America Asia

- All India

- ISO

Product Description

Technical Specifications

Load cell based Automatic & Digital Rockwell hardness tester for measureient of ferrous & non-ferrous material

Automatic Rockwell Hardness Tester with horizontal dolphin nose

Rockwell Hardness testing machine is intended for measuring hardness of different metals(Ferrous & Non-Ferrous) in an aircraft industry, also suitable for internal / external testing on curved surfaces.

1. Digital Display of hardness

2. Load cell based

3. Load cell/motorised loading/ minimum 0.1 HR Hardness display.

4. Standards : ASTM E18, ISO 6508

5. Display & Operation panel

1) Min 4 inch backlit LCD/LED screen/ panel

2) Operation through touch screen or keys

6. Language - English

7. Loading Principle and measuring operation

1) Pre-load by handle wheel manually and Automatic main load & testing cycle.

2) Curved surface auto correction.

8. Load- Pre Load:10kgf

Main Load: 60,100,150 Kgf

9. Dwell Time - 2 to 50 Seconds, Can be set in between by the panel

10. Vertical Testing - Space Min 200 mm

11. Hardness Range - 20-80HRA, 20-100 HRB, 20-80 HRC

12. Horizontal Testing Space - Min 150 mm

13. Automatic Hardness - Conversion: HRA, HRB, HRC, HRD, HRF, HV, HK,

HB, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T

14. Data Memory Function - Min 300 data should be stored in memory

15. Data Statistics - Analyzes the value of Maximum, Minimum, Average etc & Upper/Lower limit setting

16. Output - RS232 interface: mini printer optional

17. Power Supply- AC220V/50Hz

18. Accuracy - Conform to ASTM E-18, ISO-6508

19. Resolution0.1 HR

20. Temperature Range- 5 to 50 degree C

21. WeightNot more than 125 kg

22. Dimension (LXWXH)Not more than 750X300X900 mm

23. Indenter will have Indenter Protective Device

Other Products in 'Testing Machine' category

|

INNOTECH ENGINEERING DEVICES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese